Product

|

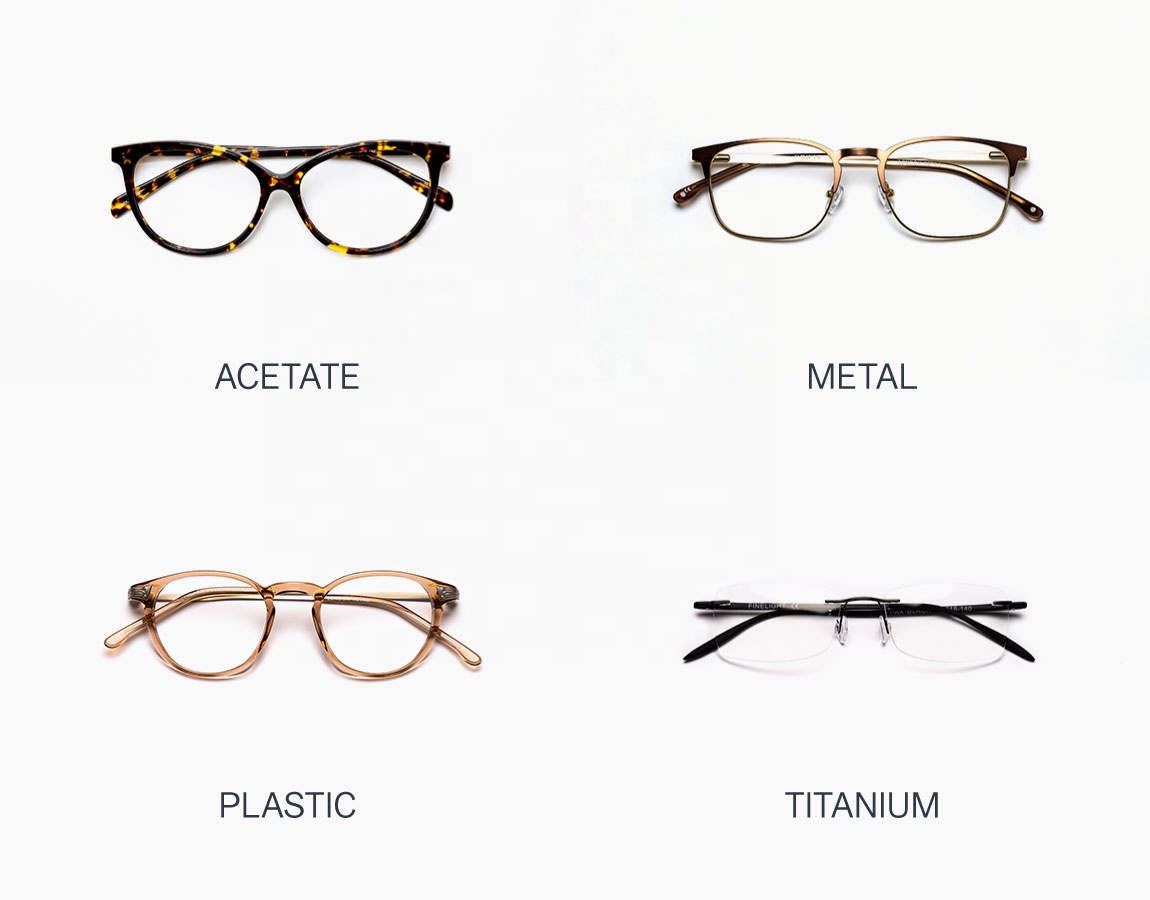

Frame |

TR90, PC, Metal in any color |

|

Lens |

AC, PC, TAC, CR39 |

|

Function |

UV400, Anti blue light, Anti fog, Polarized, Night vision, etc. |

|

Package |

1pc in polybag, 20pcs in a white box, 500pcs in a carton. Custom package is available. |

|

Delivery Time |

Stock order: in 7 days. Custom order: 7-30 Days after receiving the full deposit. |

|

Payment |

All alibaba payment terms are supported. Note: for custom order, 30% deposit before production and full payment before shipment. |

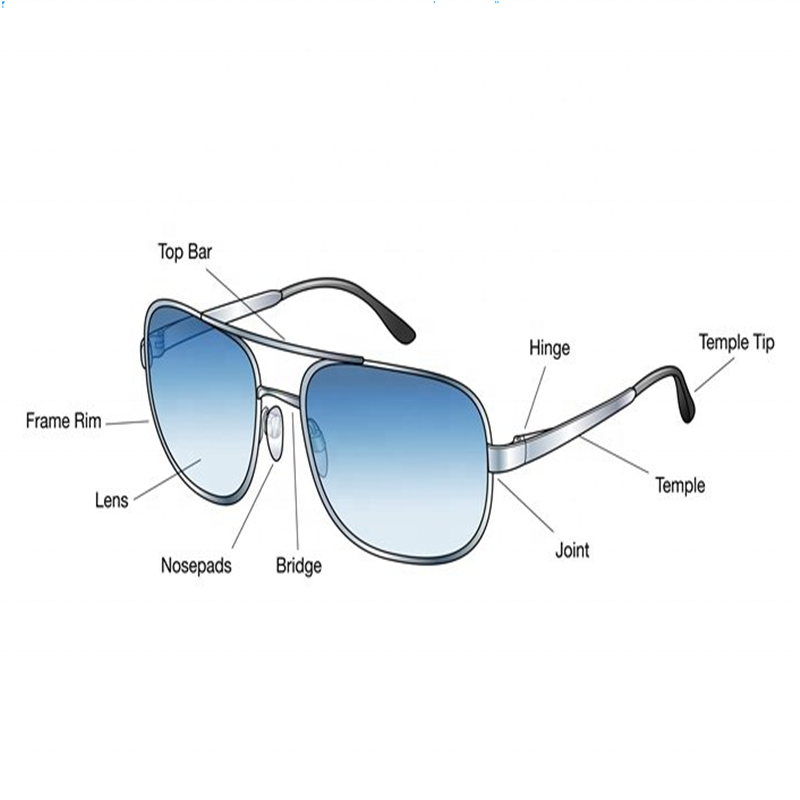

What Are the Different Parts of glasses?

Glasses are made up of three different parts: frame, temples, and lenses.

The frame includes several elements like the nose pad, bridge, and part of the hinge.

The temples include the other half of the hinge which is then fastened to the frame using a screw, glue, or heat. Each part is made individually and then assembled to create a finished pair.

After a design is created, the frames are the first to be manufactured, followed by the temples. Once the frames and temples are assembled, the lenses are created and then inserted into the frames to make a completed pair.

- How to make glasses?

Glasses are made beginning with the frames, the piece that hold the lenses. First, the size and shape of the desired frames is made using a computer before production can begin. After a design is created, the frames are made following these six steps:

Step 1: Create Steel Mold

A steel mold, or die, is created to match the desired shape of the frames. The die has sharp edges and acts like a cookie cutter for blank frames.

Step 2: Sheets of Plastic

Plastic material called cellulose-acetate is produced into thin sheets slightly wider than the frames.

Step 3: Punch Blank Frames

The sheets of plastic are heated in an oven until they become malleable and then punched with the die to create blank frames.

Step 4: Remove Excess Plastic

The blank frames are removed from the sheet, and the lens portions are removed and scrapped.

Step 5: Carve Groove for Lens

The frames are held by an aluminum holding fixture and grooves for the lenses are cut using a router blade.

Step 6: Smooth Edges

The frames are smoothed to remove rough edges using two machines. The first smooths the part that rests on the cheek, the second gets the area around the nose.

- How Are Temples Made?

After the frames have been made, the next phase is to make the temples. Glass temples are the two arms that go around your ears. These can be a different color or material than the frames, and they typically include a brand or logo. Check out how temples are made step-by-step.

Step 1: Melt Plastic

Plastic material called cellulose-acetate is melted down into thin sheets in an oven. This can be the same material or

complimentary material to the frames.

Step 2: Punch Blank Temples

Another steel die punches blank temples from the sheets.

Step 3: Insert Core Wire

The blank temples are heated, and a strip of steel called a core wire is inserted in the center of the softened plastic as reinforcement.

Step 4: Cut Hinge Slots

Slots are cut into the upper corners of the temples for hinges.

Step 5: Secure Hinges

Hinges are placed and secured using heat to melt the hinge to the frame.

- How Are Glasses Lenses Made?

Once the glass frames and temples are made, it is time to create the lenses! Glass lenses are made in six simple steps

beginning with molten plastic and ending with a fully assembled pair of glasses!

Step 1: Add Colorant

Colorant is added in one of two ways, by adding color to molten lens material, or by chemically coating finished lenses.

Step 2: Create Lens Shape

Molten plastic is cast into a mold to create a general lens shape such as round, square, or cat eye.

Step 3: Create Curve

The lens is put in a curve generator that grinds out the back of the lens.

Step 4: Trim Lenses

An edge grinder is used to shave the lenses into the shape of the frames.

Step 5: Coat Lenses

Lenses are coated with anti-reflective material using a vacuum.

Step 6: Insert Lenses into Frames

Finished lenses are snapped into the grooves of the frames.

| Product Code |

32831 |

|---|---|

| Category |

Sunglasses |